High Intensity and Engineer Grade Chevron Stripes / Tapes - NFPA 1901

High Intensity and Engineer Grade Chevron Stripes / Tapes - NFPA 1901

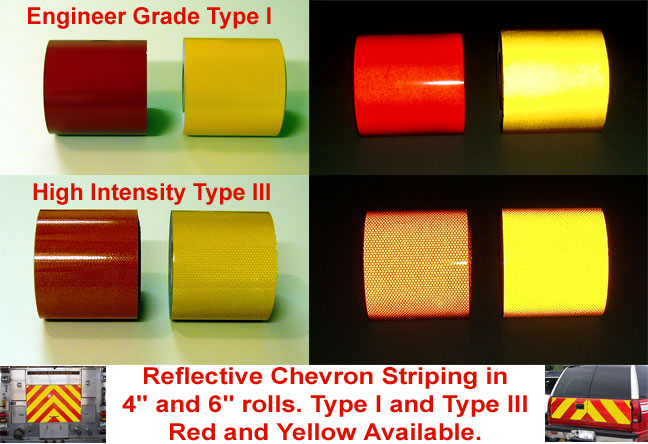

In 2009 Fire Apparatus and Emergency vehicles will be subject to new guidelines in regards to reflective striping. The new standards call for striping on the front, sides and rear of all fire and emergency apparatus. A reflective type I tape or better is recommended. Type I tapes are also referred to as engineer grade reflective films. They are the most common and the most affordable class of tape and generally carry a 7 year outdoor life. Type 3 tapes are known as high intensity reflective tape and are more expensive but are still fairly affordable. They are normally rated for 10 years outdoors. We carry the type 1 and 3 reflective sheeting in both yellow and red and in both 4" and 6" by 150 foot rolls. We carry a full line of reflective tapes at our Main Reflective Store. If you prefer a brighter prismatic tape we have those at our Reflects-Light reflective store. We carry reflective dots, overlays and squares for creating chevron striping on diamond tread plate at our Reflective Shapes Store.

The specifics of the new regulation are as follows:

NFPA 1901 Standards For Retro Reflective Striping on Fire Trucks and Emergency Vehicles

REFLECTIVE REQUIREMENTS FOR DOORS

14.1.6 Any door of the apparatus designed to allow persons

to enter or exit the apparatus shall have at least 96 in.2

(62,000 mm2) of retroreflective material affixed to the inside

of the door.

15.9.3.1* A retroreflective stripe(s) shall be affixed to at least

50 percent of the cab and body length on each side, excluding

the pump panel areas, and at least 25 percent of the width of

the front of the apparatus.

15.9.3.1.1 The stripe or combination of stripes shall be a

minimum of 4 in. (100 mm) in total width.

15.9.3.1.2 The 4 in. (100 mm) wide stripe or combination of

stripes shall be permitted to be interrupted by objects (i.e.,

receptacles, cracks between slats in roll up doors) provided

the full stripe is seen as conspicuous when approaching the

apparatus.

15.9.3.1.3 A graphic design shall be permitted to replace all

or part of the required striping material if the design or combination

thereof covers at least the same perimeter length(s)

required by 15.9.3.1.

REFLECTIVE REQUIREMENTS FOR THE REAR OF THE VEHICLE

15.9.3.2 At least 50 percent of the rear-facing vertical surfaces,

visible from the rear of the apparatus, excluding any

pump panel areas not covered by a door, shall be equipped

with retroreflective striping in a chevron pattern sloping

downward and away from the centerline of the vehicle at an

angle of 45 degrees.

15.9.3.2.1 Each stripe in the chevron shall be a single color

alternating between red and yellow.

15.9.3.2.2 Each stripe shall be 6 in. (150 mm) in width.

15.9.3.3 All retroreflective materials required by 15.9.3.1 and

15.9.3.2 shall conform to the requirements of ASTM D 4956,

Standard Specification for Retroreflective Sheeting for Traffic Control,

Section 6.1.1 for Type I Sheeting.

15.9.3.3.1 All retroreflective materials used to satisfy the requirements

of 15.9.3.1 that are colors not listed in ASTM D 4956,

Section 6.1.1, shall have a minimum coefficient of retroreflection

of 10 with observation angle of 0.2 degrees and entrance angle of

−4 degrees.

15.9.3.3.3 Any printed or processed retroreflective film construction

used to meet the requirements of 15.9.3.1 and

15.9.3.2 shall conform to the standards required of an integral

colored film as specified in ASTM D 4956, Section 6.1.1.

REFLECTIVE REQUIREMENTS FOR OTHER PARTS OF THE VEHICLE

19.18.11 Where the design of the aerial device incorporates a

knuckle, the knuckle shall be as follows:

(1) Equipped with position lights or continuously illuminated

by boom lights

(2) Painted with reflective paint or provided with retroreflective

Striping

19.21.4.3 All stabilizers that protrude beyond the body of the

apparatus shall be striped or painted with retroreflective material

so as to indicate a hazard or obstruction.

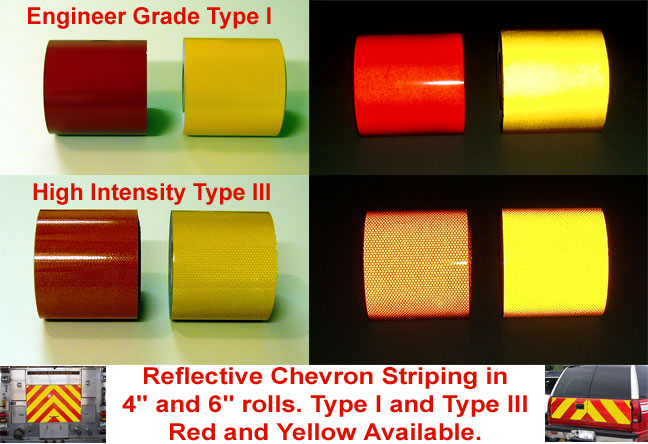

Engineer grade or Type 1 reflective tape is simply a solid color in daylight to the naked eye. When light hits the tape it is reflected to the source and the reflective tape lights up. Engineer grade type 1 tapes reflect at a rate of about 75 candlepower for white and less for other colors.

This material is commonly used on emergency vehicles and makes up the majority of the reflective lettering that you see on fire apparatus. We carry the flexible engineer grade version because it will stretch if necessary and conform making it perfect for applications on vehicles.

High intensity or type 3 reflective tape is characterized by a honeycomb pattern (encapsulated lens reflective tape). Within each honey comb grid there are high concentrations of glass beads. This concentration of beads makes for a much brighter tape. High Intensity tapes reflects at a rate of around 250 candlepower for the white and less for other colors. Orange safety cones and road barrels use this material as well as many street signs. Quite a few fire departments prefer the high intensity type 3 material because it can be seen from further away and has a longer outdoor life.

Click Here for Engineer Grade Type I Reflective Tape in 4" Widths

Click Here for Engineer Grade Type I Reflective Tape in 6" Widths

Click Here for High Intensity Type III Reflective Tape in 4" or 6" Widths

Click Here to see our Pre-Made Reflective Chevron Panels

Click Here to see all of our Widths, Colors and Types of Reflective Tapes.

Click Here to see our Pavement Marking Tapes and Road Markers.

To visit our main safety products site Click Here.

Good Article on Accident Reduction through Visibility Enhancement Click Here.

If you have any questions about which tape is right for your application or need samples feel free to email me at steve@reflectivestore.com

Steve Cole - Owner

850-934-3157